Product Description

Industries Using Our Dunnage Bags

Electronics,Refrigeration,Shipping, Wine Industry, Food Processing, Paper Industry, Container Transport, Bricks / Plasterboard,Chemicals,Furniture, Cargo Handling, Ceramic/Tiles, Pharmaceuticals, MachineryManufacturers, EdibleOil, GlassIndustry, Packaging Industry.

We manufacture two types of dunnage air bags: the Kraft paper&woven pp laminated dunnage bag and the PP woven dunnage bag. Each is available in a large variety of sizes and strengths. They fill up every space in every form up to 55 cm, so there is almost always a dunnage bag to suit your freight. And while other dunnage material can damage your cargo, all dunnage air bags are completely safe for goods and users. Securing cargo has never been so simple and effective to do. In addition, our dunnage bags are also attractively priced.

Kraft paper&pp laminated dunnage air bags:

Our extraordinarily strong and durable Kraft paper&pp laminated dunnage bags consist of a special airtight inner bag of polyethylene with one or more outer layers of moisture-resistant quality Kraft paper laminated with woven pp fabric.

|

|

|

|

PP woven dunnage bags:

Our PP woven dunnage bags have a unique airtight inner bag of polyethylene just like the Kraft paper&pp laminated dunnage bags. However, the outside is made of woven polypropylene (PP). A very strong, durable and water-resistant material. Perfect for transport by sea, but the dunnage air bags can also be used at other locations.

|

|

|

|

Dimension in MM:

| 800 X 800 MM | 900 X 1200 MM | 1000 X 1000 MM |

| 800 X 1000 MM | 900 X 1500 MM | 1000 X 1200 MM |

| 800 X 1200 MM | 900 X 1800 MM | 1000 X 1800 MM |

| 800 X 1500 MM | 900 X 2100 MM | 1000 X 2200 MM |

Inspite of using the best packaging materials to pack your valuable products, they do not reach your costumer the same way you want.

Reason: voids and space inside container and between pallets allow the cargo to bang between themshelves and the damage is done.

Solution: proper selection and use of cargo securing bags or dunnage air bags to secure your cargo.

Other names of dunnage air bags are... - Dunnage bags, - inflatable bags, - Kraft paper bags, - void fillers, - air cushion

What are dunnage air bags?

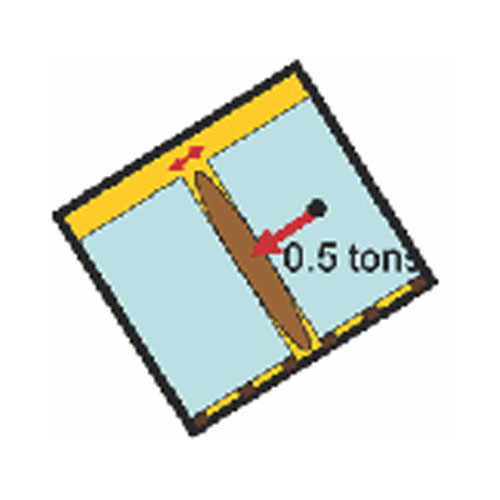

A dunnage bag consists of a closed chamber made from a plastic bag filled with air, covered by one or more layers of Kraft paper and/orKraft paper laminated with woven polypropylene and/or woven polypropylene. Dunnage air bags secure and stabilize your cargo in sea-containers, closed railcars, trucks and (ocean going-) vessels

How do dunnage bags work?

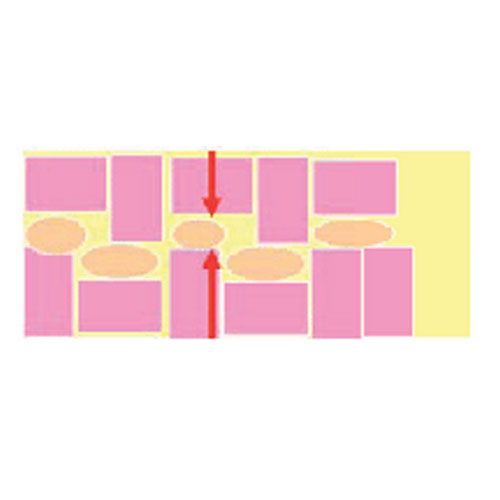

A dunnage bag is placed in the void between cargos (hence their name “void fillers”). Upon inflation, cargo is being 'pushed' to the sides of a compartment (e.g. container walls). It is extremely important to determine the size of the bag by the void that needs to be filled. Simply said, the bigger the void the wider the bag has to be to be able to fill the gap without looking like a football lost between two goalposts! If this does not match, your dunnage bag can and will not do a proper job. This can result in cargo movement during transport and can cause damage to cargo and people.

Benefits of Dunnage bag:

1. Absorb Lateral Forces

2. Absorb Longitudinal Forces

3. Prevent Sideway Sliding And Tipping

4. Prevent Longitudal Tipping

5. Prevent Vertical Movement And Acts As A Void Filler

How do you choose the right dunnage bag for you?

Several factors need to be taken into consideration upon selecting the best bag for your cargo securing job,

such as:

Application; e.g. truck or reefer container,

Reusability; is the bag going to be reused

Recycling; does the bag have to be recycled

Performance required; criteria could be:

a. Moisture resistance

b. Durability (wear and tear)

c. Puncture resistance

d. Rigidity

e. Strength

f. Slippage/friction bag and cargo

g. Filling technology

h. Deflation and time to deflate

i. Cost

How do you determine the right size of bag you need?

Dunnage bags are available in a huge amount of sizes, how do you know which one fits your requirements? Let's briefly touch that subject. Besides the right type of dunnage bag, the size of the bag is equally important and can be determined in three easy steps.

1. Measure the void between the cargos

Rule of thumb for calculating the required width of a dunnage bag; measure the void and multiply this number by 2 and add 5 on top of the outcome, then look for the nearest wider bag. This means:

• Void of 25 cm requires a 60 cm bag (25x2+5=55. Next nearest wider bag = 60 cm)

• Void of 40 cm requires a 90 cm bag (40x2+5=85. Next nearest wider bag = 90cm)

• Void of 45 cm requires a 100 cm bag (45x2+5=95. Next nearest wider bag = 100cm)

• Void of 55 cm requires a 120 cm bag (55x2+5=115. Next nearest wider bag = 120cm)

2. Measure distance from the floor to top of the load

3. Measure length of pallets or any other type of cargo you are securing

The dunnage bag should cover as near as possible the full height and length of the pallets or cargo units being secured. Any dunnage bag expert will now be able to tell you what size your dunnage bag should be. If you want some information from our experts just contact us and fill out a contact form.

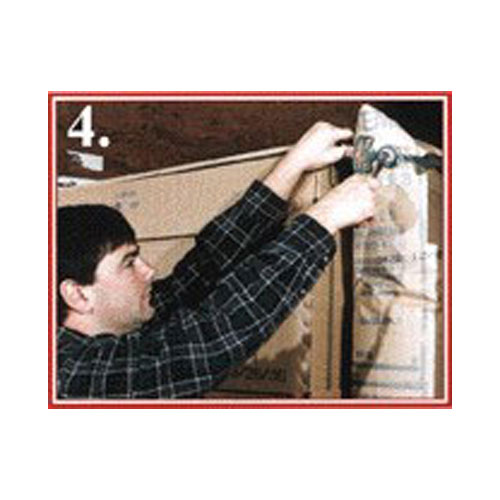

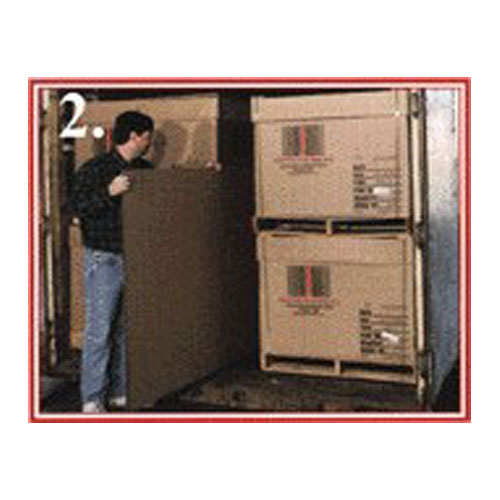

How to Install the Bag?

Step 1: Choose the right size for maximum contact

Step 2: Protect the bag from sharp objects

Step 3: Position the bag correctly

Step 4: Inflate the bag till the cargo is properly secured