Product Description

2.jpg) |

In manufacture of webbings 100% high tenacity polyester yarn is used , with relative density is 1.38 & melting point is 260 deg. Centigrade. Elasticity is < 3% elongation at safe working load & recovery is 95% after 24 hours. Its electrical resistance at dry state tends to infinity.At breaking strength its elongation is less than 10%.It does not loose strength as a result of moisture absorption.

Type of Polyester webbing slings

- Simplex Eye & Eye webbing slings

These are made of single layer of webbing with reinforced eye loops at both ends. These are preferred for their wider load bearing surface - Duplex Eye & Eye Webbing slings

These are made of two layers of webbing with reinforced eye loops at both ends. These are the widely used slings for normal load lifting applications - Triplex/Quadraplex Eye & Eye webbing slings

These are made of Three/Four Layers of webbing with reinforced eye loops at both ends. These are meant for lifting heavier loads. - Flat Endless webbing slings

These are made from flat webbings by sewing the ends together and making it endless like rubber band.

POLYESTER WEBBING SLINGS AS PER EN 1492 – 1,IS 15041-2001 AND ASME B 30.9

Vertical Straight lift |

Colour |

Width |

Choker |

Basket |

Basket 45 |

Basket90 |

1 Ton |

violet |

25 mm 2 ply |

800 kg |

2000 kg |

1800 kg |

1400 kg |

2 Ton |

Green |

50 mm 2 ply |

1600 kg |

4000 kg |

3600 kg |

2800 kg |

3 Ton |

Yellow |

75 mm 2 ply |

2400 kg |

6000 kg |

5400 kg |

4200 kg |

4 Ton |

grey |

100 mm 2 ply |

3200 kg |

8000 kg |

7200 kg |

5600 kg |

5 Ton |

Red |

125 mm 2 ply |

4000 kg |

10000 kg |

9000 kg |

7000 kg |

6 Ton |

Brown |

150 mm 2 ply |

4800 kg |

12000 kg |

10800 kg |

8400 kg |

8 Ton |

Blue |

200 mm 2 ply |

6400 kg |

16000 kg |

14400 kg |

11200 kg |

10 Ton |

Orange |

250 mm 2 ply |

8000 kg |

20000 kg |

18000 kg |

14000 kg |

12 Ton |

Orange |

300 mm 2 ply |

9600 kg |

24000kg |

21600 kg |

16800 kg |

15 Ton |

Orange |

250 mm 3 ply |

12000 kg |

30000 kg |

27000kg |

21000 kg |

16 Ton |

Blue |

200 mm 4ply |

12800kg |

32000 kg |

28800 kg |

22400 kg |

20 Ton |

Orange |

250 mm 4ply |

16000 kg |

40000 kg |

36000 kg |

28000 kg |

24 Ton |

Orange |

300 mm 4ply |

19200 kg |

48000 kg |

43200 kg |

33600 kg |

HOW TO ORDER POLYESTER WEBBING SLINGS :

AS PER WHAT STANDARD YOU WANT THEN WIDTH X CAPACITY X EFFECTIVE LENGTH IN MTRS

For example As per ASME B 30.9, 50 mm x 2 t x 3 mtr means 50 mm width , 2 t cap , 3 mtr long As per ASME B 30.9 Standards.

Guidelines for the safe use of flat duplex woven webbing sling

Use of flat woven webbing slings in adverse conditions or hazardous applications

Chemical -

The material from which flat webbing slings are manufactured have selective resistance to chemicals. The resistance of man-made fibers to chemicals is summarized below:-

a) polyester (PES) is resistant to most mineral acids but is damaged by alkalis;

b) polyamides (PA) are virtually immune to the effect of alkalis; however, they are attacked by mineral acids;

c) polypropylene (PP) is little affected by acids or alkalis and is suitable for applications where the highest resistance to chemicals other than solvents is required.

Solutions of acids or alkalis which are harmless can become sufficiently concentrated by evaporation to cause damage.

Contaminated slings should be taken out of service at once, soaked in cold water, dried naturally and referred to a competent person for examination.

Slings with grade 8 fittings and multi-leg slings with grade 8 master links should not be used in acidic conditions. Contact with acids or acidic fumes causes hydrogen embrittlement to grade 8 materials.

If exposure to chemicals is likely, the manufacturer or supplier should by consulted.

Temperature -

Flat woven webbing slings are suitable for use and storage in the following temperature ranges:

a) polyester and polyamide: -40 ° C to 100 ° C,

b) polypropylene: -40 ° C to 80 ° C.

At low temperatures ice formation will take place if moisture is present. This may act as a cutting agent and an abrasive causing internal damage to the sling. Further, ice will lessen the flexibility of the sling, in extreme cases rendering it unserviceable for use.

These ranges vary in a chemical environment, in which case the advice of the manufacturer or supplier should be sought. Limited indirect ambient heating, within these ranges, is acceptable for dyeing.

Cutting and abrasion - webbing slings are susceptible to cutting and abrasion from sharp edges or heat generated from abrasion. Protective sleeves or suitable packing should be used where necessary.

UV degradation - The man-made fibers from which the webbing is produced are susceptible to degradation if exposed to ultraviolet

Radiation. Flat woven webbing slings should not be exposed or stored in direct sunlight or sources of ultra-violet radiation.

Inspection of flat woven webbing slings in service

First use - Before first use of the sling it should be ensured that:

a) the sling corresponds precisely to that specified on the order;

b) the manufacturer’s certificate has been issued showing compliance to the required standard;

c) the identification and WLL marked on the sling correspond with the information on the certificate.

Before and during each use -

Before each use, the sling should be inspected for defects and to ensure that the identification and specification are correct. A sling that is unidentified or defective should never be used, but should be referred to a competent person for examination.

During the period of use, frequent checks should be made for defects or damage, including damage concealed by soiling, which might affect the continued safe use of the sling. These checks should extend to any fittings and lifting accessories used in association with the sling. If any doubt exists as to the fitness for use, or if any of the required markings have been lost or become illegible, the sling should be removed from service for examination by a competent person.

The following are examples of defects or damage likely to affect the fitness of slings for continued safe use.

a) surface chafe - In normal use, some chafing will occur to the surface fibers. This is normal and has little effect. However ,the effects are variable and as the process continues, some loss of strength should be expected. Any substantial chafe ,particularly localized, should be viewed critically. Local abrasion, as distinct from general wear, can be caused by sharp edges whilst the sling is under tension, and can cause serious loss of strength.

b) Cuts - cross or longitudinal cuts, cuts or chafe damage to selvedges, cuts to stitching or eyes.

c) chemical attack - chemical attack results in local weakening and softening of the material. This is indicated by flaking of the surface which may be plucked or rubbed off.

d) heat or friction damage. This is indicated by the fibers taking on a glazed appearance and in extreme cases, fusion of the fibers can occur.

e) damaged or deformed fittings.

Correct selection and use of flat woven webbing

When selecting and specifying slings made from man-made fibers, consideration should be given to the required working load limit ,taking into account the mode of use and the nature of the load to be lifted. The size, shape and weight of the load, together with the intended method of use, working environment and nature of the load, all affect the correct selection.

Mode factor - The selected sling should be both strong enough and of the correct length for the mode of use. The mode factor should be considered as it will effect the sling Working Load Limit. If more than one sling is used to lift a load, these slings should be identical. The material from which the webbing is made should not be affected adversely by the environment or the load .Consideration should also be given to ancillary fittings and lifting devices which should be compatible with the sling(s). The termination of the sling should also be considered i.e. whether fittings or soft eyes are required.

Flat woven webbing slings should not be overloaded; the correct mode factor should be used (see table). Working load limits for some modes may be given on the label. In the case of multi-leg slings the maximum angle to the vertical should not be exceeded.

Personnel safety- Care should be taken to ensure the safety of personnel during the lift. Persons in the danger area should be warned that the operation is to take place and, if necessary, evacuated from the immediate area. Hands and other parts of the body should be kept away from the sling to prevent injury as the slack is taken up. Reference should also be made to ISO 12480-1 for planning and management of the lifting operation and the adoption of safe systems of working .

Trial lift- A trial lift should be made. The slack should be taken up until the sling is taut. The load should be raised slightly and a check made that it is secure and assumes the position intended. This is especially important with basket or other loose hitches where friction retains the load. If the load tends to tilt, it should be lowered and attachments re-positioned. The trail lift should be repeated until the stability of the load is ensured.

Care should be taken when making the lift to ensure that the load is controlled, e.g. to prevent accidental rotation or collision with other objects. Snatch or shock loading should be avoided, as this will increase the forces acting on the sling. A load in the sling or the sling itself should not be dragged over the ground or rough surfaces.

Lowering the load- The load should be lowered in an equally controlled manner as when lifted. Trapping the sling when lowering the load should be avoided. The load should not rest on the sling, if this could cause damage and pulling the sling from beneath the load when the load is resting on it should not be attempted.

Sling storage after use- On completion of the lifting operation the sling should be returned to proper storage. When not in use, slings should be stored in clean, dry and well ventilated conditions, at ambient temperature and on a rack, away from any heat sources, contact with chemicals, fumes, corrodible surfaces, direct sunlight or other sources of ultra-violet radiation .Prior to placing in storage, slings should be inspected for any damage which may have occurred during use. Slings should never be

returned damaged to storage .Where lifting slings have come into contact with acids and/or alkalis, dilution with water or neutralization with suitable media is recommended prior to storage. Depending on the material of the lifting sling and on the chemicals referred to in D.1.1, it may be necessary in some cases to request from the supplier additional recommendations on the cleaning procedure to be followed after the sling has been used in the presence of chemicals. Slings which have become wet in use, or as the result of cleaning, should be hung up and allowed to dry naturally.

Examination and repair - Examination periods should be determined by a competent person, taking into account the application, environment, frequency of use and similar matters, but in any event slings should be visually examined at least annually by a competent person to establish their fitness for continued use. Records of such examinations should be maintained. Damaged slings should be withdrawn from service. Never attempt to carry out repairs to the slings yourself.

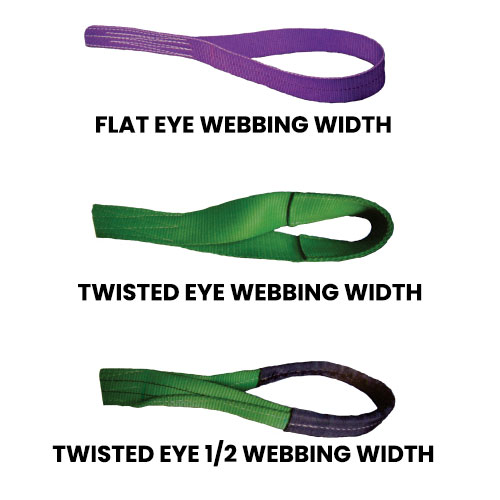

Type Of Eye